The process of casting in real world

Casting

Geometric Aspects of the Casting Process

Manufacturing is the process of converting raw materials (such as iron, glass or polymer) to useful products, ranging from goods such as kettles and telephones to machinery such as railway locomotives and aircrafts. By means of computer-aided design (CAD) and computer-aided manufacturing (CAM), these manufacturing processes have been done in a form of automation, both in design phase and construction phase. Due to the geometric nature of manufacturing processes, many geometric problems has arised in it. Computational geometry arises at all levels of manufacturing, from design, modeling and simulation, to process planning, on-line verification and testing.

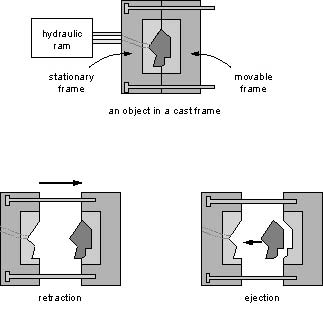

In casting, liquid is poured into a cast that has a cavity with the shape of the object to be manufactured. The liquid then hardens, after which the cast is removed and one is left with an object whose shape is that of the cavity. The key property necessay for casting is that the cast parts can be removed from the object without destroying either the cast parts or the object. This ensures that the given object can be mass produced by re-using the same cast parts.

Papers published or submitted for publication

Separating an Object from its Cast

We consider the case where the cast consists of two parts and address the following problems.

(1) Given a cast for an object and a direction d, can the cast be partitioned into two parts

such that the parts can be removed in directions d and -d, respectively, without colliding

with the object or the other cast part? (2) How can one find a direction d such that

the above cast partitioning can be done? We give necessary and sufficient conditions for both

problems, as well as algorithms to decide them for polyhedral objects.

with Mark de Berg, Prosenjit Bose, Siu-Wing

Cheng, Dan Halperin, Jirí Matousek, and Otfried Schwarzkopf

In Proc. 13th Annu. ACM Symposium on Computational

Geometry, 221--230, 1997 and in

Computer-Aided Design, 34(8):547-559,

2002

Casting with Skewed Ejection Directions

We

give necessary and sufficient conditions to test the feasibility of

the cast part retraction and object ejection, where retraction and

ejection directions need not be the same. For polyhedral objects,

we show that the test can be performed in O(n^2\log^2 n) time and

the cast parts can be constructed within the same time bound. The

complexity of the cast parts constructed is worst-case optimal. We

also give a polynomial time algorithm for finding a feasible pair of

retraction and ejection directions for a given polyhedral object.

with Siu-Wing Cheng, and Otfried Cheong

In Proc. 9th Annu. International Symposium on Algorithms and

Computation, 1998, and in

Algorithmica, 44(4):325-342, 2006

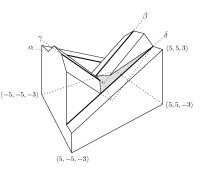

Casting with Directional Uncertainty

We consider directional uncertainty: given a 3-dimensional polyhedral object, is there

a polyhedral cast such that its two parts can be removed in opposite directions

with uncertainty \alpha without inflicting damage to the object or the cast

parts? We give a necessary and sufficient condition for castability, and a randomized algorithm

that verifies castability and produces two polyhedral cast parts for a polyhedral object of

arbitrary genus. Its expected running time is O(n\log n). The resulting cast parts

have O(n) vertices in total. We also consider the case where the removal direction

is not specified in advance, and give an algorithm that finds all feasible removal directions

with uncertainty \alpha in expected time O(n^2\log n/\alpha^2).

with Otfried Cheong, and René van Oostrum

In Proc. 13th Annu. International Symposium on Algorithms and

Computation, 2002, and in Computational Geometry: Theory and Applications,

26(2):129-141,

2003

The Reflex-Free Hull

We propose a hull operator, the reflex-free hull, that allows us to

define a 3D analogue to bays in polygons. The reflex-free hull allows a rich

set of topological types, yet for polyhedral input with $n$ edges, it remains

a polyhedral set with O(n) edges. This is in contrast to other possible

hull definitions that give non-planar surfaces and higher combinatorial

complexity. The reflex-free hull is related to identifying cavities in

computer aided design and manufacturing, but we sketch examples to indicate

that computing a reflex-free hull will be a challenging problem.

with Siu-Wing Cheng, Otfried Cheong, and Jack Snoeyink

In Proc. 13th Canadian Conference on Computational

Geometry, 2001, and in International Journal of Computational Geometry and Applications,

14(6):453-474, 2004

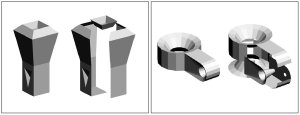

Casting an Object with a Core

This

paper addresses geometric problems that concern manufacturing an

object using a cast with a core. In casting, molten material

is poured into the cavity of the cast and allowed to solidify. The

cast has two main parts to be removed in opposite parting directions.

To manufacture more complicated objects, the cast may also

have a core to be removed in a direction skewed to the parting directions.

In

this paper, given an object and the parting and core directions,

we give necessary and sufficient conditions to verify whether a

cast can be constructed for these directions. In the case

of polyhedral objects, we develop a discrete algorithm to perform

the test in $O(n^3\log n)$ time, where $n$ is the object size. If

the test result is positive, a cast with complexity $O(n^3)$ can

be constructed within the same time bound. We also present

an example to show that a cast may have $\Theta(n^3)$ complexity

in the worst case. Thus, the complexity of our cast is worst-case

optimal.

with Sang-Won Bae, Siu-Wing Cheng, and

Kyung-Yong Chwa

In Proc. 16th Annual International Symposium

on Algorithms and Computation 2005. To appear in Algorithmica.

More details available [ PDF]

My thesisis available [ online]